measuring minimum wall thickeness in a 3d model|how thick is 3d printing : bulk 3D Wall Thickness analyzes a plastic part for areas that are too thick or too thin to manufacture properly, according to maximum or minimum tolerances that you specify. The results show your 3D model in the viewport, color-coded according to areas that are above, within, and below the tolerance limits. WEBAcesse sua conta. Para acessar a sua conta, você precisa baixar o aplicativo. app Itaú. Um app cada vez mais completo, para você contar com diversos serviços do banco .

{plog:ftitle_list}

Resultado da 13 de fev. de 2024 · Últimas Notícias de Moçambique e do mundo. Acopanhe os últimos acontecimentos da Sociedade, Economia, Política e Saúde no Jornal de Notícias de Hoje.

For example, a material like PLA has a minimum wall thickness of 0.8 mm (though in certain cases that could be lower), but the ideal is closer to 1.5 mm. Walls are an important part of any 3D print. Learn how to find the perfect wall thickness for your 3D prints!3D Wall Thickness analyzes a plastic part for areas that are too thick or too thin to manufacture properly, according to maximum or minimum tolerances that you specify. The results show your 3D model in the viewport, color-coded according to areas that are above, within, and below the tolerance limits.Minimum Wall Thickness by 3D Printing Process. Minimum wall thickness varies based on the type of 3D printer. You can use these design guidelines below as a starting point for choosing the right wall thickness for your model .

If you make a thin figurine measuring 5 CM then a 0.4mm wall could keep that figurine upright. Meanwhile if you now want to 3D Print the same model at 30 CM it might become too fragile or fail. . 3DPrepPro minimum wall thickness adjustment slider. To avoid wall thickness problems with your 3D model. Upload it to 3DPrepPro and let our .

Minimum wall thickness in 3D printing basically means having the least possible filament thickness without losing the quality of your structure. . You can set a smaller scale of your model. There are plenty of scaling calculators out there for you to use. If you want to know if your structure is good, simply rescale it to a smaller size and .

Even when applying the 0.5mm thickness the measurement tool is returning <0.5mm thicknesses. Is there a better way? Ideally I am looking to see a minimum wall thickness for the entire model as a baseline, so then I can perhaps apply Solidify modifier to only specific vertex groups to bump up the wall thickness only in certain problem areas. Click Create in the toolbar; Select Measure Tools > Distance Tool; Hold down X and click on two corners of an element you want to measure the thickness; Why is wall thickness important? As stated above, wall thickness is the value that gives a 3D model durability and strength. Too thin walls for large surfaces of a model can be ruined by the printer simply .

Edit: I selected the whole model using control and selected make solid. Set the mode from fast to accurate. I set the solid accuracy and mesh density to anywhere from 300 to 500. Then I slowly increase offset distance until the holes are sealed. I leave the minimum thickness at 0 because it doesn't appear to help much. Minimum Wall Thickness of 3D Printing. . Consequently, small-scale models should have low wall thickness values, while large-scale models use a thicker wall value. . However, measuring the strength of a 50% infill will be relative to a higher or lesser percentage of the same materials and designs. For example, if a project has a 50% infill .Discover the importance of wall thickness for 3D printing. Learn how to determine optimal thickness to ensure your prints are strong, functional, and cost-effective! . Flexible Filaments – At least maintain structural integrity of model at any given time so minimum limit must never fall below 1.5 mm . Use calipers to measure various .

Most 3D printers have a minimum resolution limit. If your model has areas that are thinner than this limit, it may result in weak points or printing failures. The Measure Thickness tool creates a color-coded map of your model, allowing you to quickly spot thin regions that might cause issues.In this video, we will show you different ways on how to add more thickness to your 3D models (STL) in Meshmixer, using the Ironman mask.*** Activate the sub.The aim of this work is measurement of wall thickness of a building, which was built to protect the Alaaddin Palace, creating of cross-section by laser scanning data. We surveyed the building by TLS and performed 3D model. Then cross-sections were created from point clouds to measurement wall thickness of concrete building. The minimum wall thickness value a 3D printer can handle is something to keep in mind when determining the wall thickness you will be using, as going for a value that is lower than this won’t have an effect due to it being rounded up to the minimum value. . considering that 3 to 4 wall lines are suitable for a typical 3D printed model, the .

In addition, a 3D model of the pipe exterior was constructed with the assumption that the pipe exterior is not damaged (e.g. non-aggressive groundwater) , using the available data of measured wall .Join Ryan Kittleson for an in-depth discussion in this video, Measuring thickness, part of Meshmixer: Additive Manufacturing Job Preparation.

The minimum scale of your model The modeling of your 3D file doesn’t necessarily require that you work with a given unit or scale. It’s particularly true with software like Blender in which you’re able to give proportion but no unit. This job will be done after the modeling phase when you send your model to a 3D printer.

Minimum Wall Thickness by 3D Printing Process. Minimum wall thickness varies based on the type of 3D printer. You can use these design guidelines below as a starting point for choosing the right wall thickness for your model based on the 3D printing process you’re planning to use:

The printable wall thickness of a 3D model will depend on many factors. These factors may include materials used, size and overall design of the 3D part. . Minimum wall thickness. For strong materials such as stainless steel and titanium, the minimum wall thickness can go as thin as 0.3mm and 0.4mm respectively.The wall thickness defines and Cura the thickness of all wall lines including the outermost wall. The wall line count is calculated from the wall thickness and the wall line width (round up or down to whole number). The wall thickness is located in Cura under the settings for the walls. Each print has a specific function.

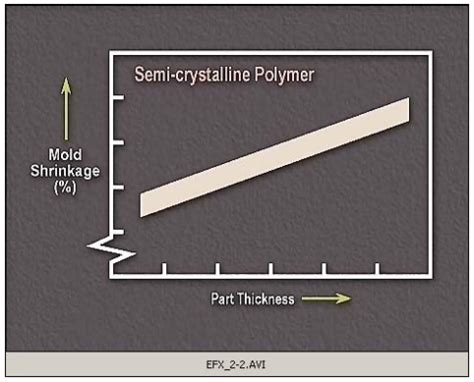

high glass transition temperature means less creep

Dimensional accuracy. Dimensional accuracy does not relate to the detail of your model but to its deviation from the nominal measurement. The general accuracy for 3D-printed metal is better than or equal to the industry standards DCTG 6 of DIN EN ISO 8062-3: 2008-09 for dimensions between 0.5 and 30 mm, DCTG 8 of DIN EN ISO 8062-3: 2008-09 for dimensions between 30 . The aim of this work is measurement of wall thickness of a building, which was built to protect the Alaaddin Palace, creating of cross-section by laser scanning data. We surveyed the building by .

There is a minimum thickness that a 3D printed part needs to have to be able to hold up at all. . When it comes to wall thickness vs infill, it’s better to use wall thickness for strength. A model with 0% infill and a 3mm wall will be very strong, while a model with a 0.8mm wall and 100% infill won’t be as strong. .Wall thickness is simply the distance between one surface of your model and its opposite sheer surface. Many printing problems can be traced back to wall thickness issues. The minimum printable wall thickness primarily depends on the 3D printing material you choose. However, other factors, such as the alignment, size, and overall design of your . The minimum wall thickness of 3D printing materials varies depending on the specific filament or material being used. It is important to understand the wall thickness requirements for different materials in order to achieve optimal print quality. . – Use slicing software to visualize and adjust the wall thickness of the model. – Learn . Assigning the wall thickness to your 3D model 3D metal printing thickness . and design specifications also play an important role in deciding the minimum thickness of the wall. Before starting the process of 3D printing, one should focus on the design part. One should be aware of the guidelines specified for the material that has to be 3D .

3D Printing Minimum Wall Thickness. 3D printing minimum wall thickness is the thinnest wall that a 3D printer can reliably print without compromising the structure of the object. This value varies depending on the printing material and the printer’s capabilities. For instance, with FDM printers, a common minimum wall thickness 3d printing is .

why is wall thickness important

high glass transition temperature means more creep

high temperature ceramics creep resistant material

high temperature creep is a diffusion controlled process

high temperature creep metals

18 de ago. de 2023 · GammaRayDeviantArt on DeviantArt https://www.deviantart.com/gammaraydeviantart/art/First-Ever-Kiff-Post-Kiff-Fixed-R34-977787632 GammaRayDeviantArt

measuring minimum wall thickeness in a 3d model|how thick is 3d printing